-

Fast Delivery Dispatch in 24 hrs

Fast Delivery Dispatch in 24 hrs

-

Satisfaction Guaranteed.

Satisfaction Guaranteed.

-

Secure Payments

Secure Payments

-

Need help? Call Us 01744 520 110 or email sales@industrialsuppliesco.co.uk

Need help? Call Us 01744 520 110 or email sales@industrialsuppliesco.co.uk

Our Clients

Description

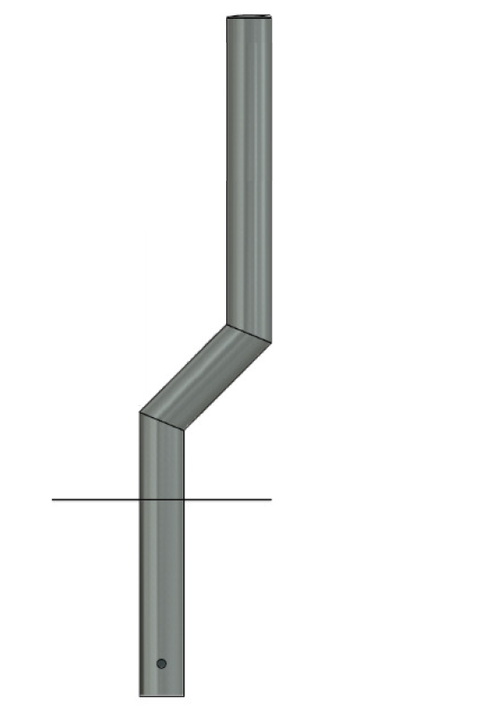

Safeguard buildings, columns, posts, and walkways from vehicle impact with this 1100 mm Cranked Safety Bollard. Engineered for durability, with a distinctive offset (cranked) profile to provide clearance where needed, this bollard delivers both protection and aesthetic appeal—ideal for commercial, industrial, or premium sites.

Key Features & Benefits

- Offset (Cranked) Design — Creates a purposeful gap, allowing protection of structures, columns, or posts without interfering with adjacent surfaces.

- Heavy-Duty Materials — Available in galvanised mild steel or Grade 304 stainless steel for long-term corrosion resistance.

- Impact-Resistant Construction — 3 mm wall for galvanized option, 2 mm for stainless steel—built for demanding environments.

- Concrete-In Mount (Approx. 400 mm) — Provides secure anchoring in concrete foundations for stable performance.

- Clean & Professional Appearance — Sleek profile that suits both modern and traditional surroundings.

- Low Maintenance — Designed to endure impacts and environmental exposure with minimal upkeep.

Typical Specifications

| Parameter | Example / Option |

|---|---|

| Height Above Ground | 1,100 mm |

| Diameter / Width | 101 mm (also 114 mm variant) |

| Material / Finish | Galvanised mild steel; Galvanised + powder coated; Grade 304 stainless steel |

| Mount Type | Concrete-in (approx. 400 mm embed) |

| Wall Thickness | 3 mm (galvanised), 2 mm (stainless) |

Use Cases & Applications

- Protecting building corners, posts, or columns near driveways and traffic paths

- Shielding vulnerable structures (speaker posts, signage poles) from vehicle damage

- Use in drive-thru lanes, commercial premises, shopping centres, car parks

- Industrial settings where offset design helps avoid direct contact with walls

- Sites that demand a professional aesthetic alongside safety functionality

Installation & Best Practices

- Prepare the foundation — excavate a suitable hole (~400 mm deep) and pour concrete base.

- Position the bollard — ensure correct alignment and offset orientation before the concrete sets.

- Backfill & compact — secure the base, ensuring the bollard is upright and stable.

- Surface finishing — optionally apply powder coating or paint, especially for coated variants.

- Regular inspection — check for damage, alignment, and corrosion. Replace or repair as needed.

About Us

Suppliers to Ministry of Defence, NATO, US Airforce and Most UK Councils, Schools, Universities, Hospitals & various Government departments

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.